5+1 Axis Bridge Saw

The 5+1 Axis Bridge Saw Machine (Model: ZLBS-500CNC/5+1) is a high-performance CNC equipment designed for processing marble, granite, porcelain, and quartz stone countertops, equipped with a camera, milling head, vacuum cups, and pressure plate cylinders to integrate multiple functions and meet diverse stone processing needs; as a fully automatic machine, it realizes one-click automatic processing—after image scanning, the CNC system automatically generates cutting programs to eliminate manual intervention and improve efficiency, and powered by a standard 22KW permanent magnet motor, it saves up to 40% energy compared to conventional motors, reducing operational costs significantly, while also boasting high-end intelligent functions including remote control, remote programming, and remote fault diagnosis for convenient operation and timely maintenance, plus the main body can be loaded into a high-cube container to facilitate international transportation, with OEM/ODM services available to customize the machine according to specific customer requirements.

Quick Information

Key Features & Advantages

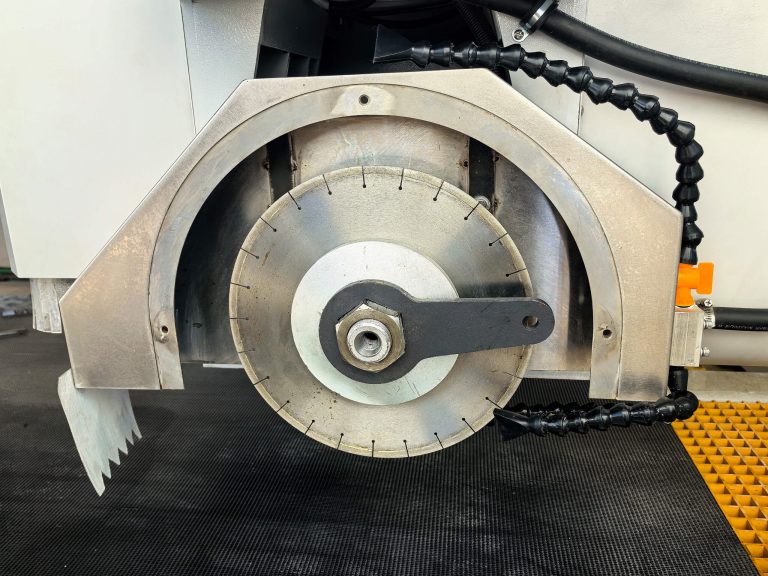

5+1 Axis Multifunctional Processing

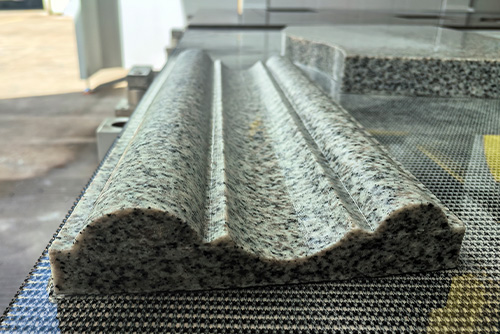

Integrates camera, milling head, vacuum cups, and pressure plate cylinders to handle marble, granite, porcelain, and quartz countertops, meeting diverse stone processing needs.

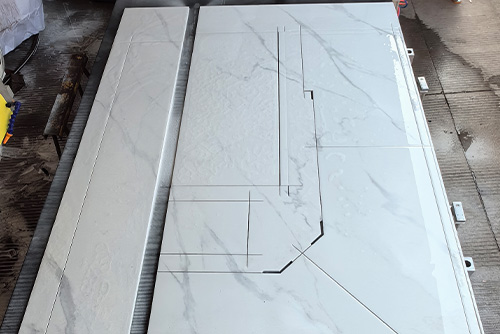

Auto Visual Positioning & Programming

After image scanning, the CNC system automatically generates cutting programs for one-click automatic processing, eliminating manual intervention and boosting efficiency.

High-Efficiency Permanent Magnet Motor

Powered by a 22KW permanent magnet motor that saves up to 40% energy compared to conventional motors, significantly reducing operational costs.

Remote Intelligent Operation & Maintenance

Supports remote control, remote programming, and remote fault diagnosis for convenient operation and timely troubleshooting.

High-Cube Container Compatible

The main body of the machine can be loaded into a high-cube container, facilitating international transportation and logistics.

Flexible OEM/ODM Solutions

Customizable configurations and services to tailor the machine to specific production requirements and branding needs.

Technical Specifications

| Model | ZLBS-500CNC/5+1 |

|---|---|

| Worktable | Material: PVC+Rubber; Size: L3500×W2000 mm |

| Max. Cutting Size | L3500×W2000×T120 mm |

| Max. Chamfering Size | L3500×W2000×T80 mm |

| Cylinders | 5 Groups |

| X/Y/Z-axis Transmission | Taiwan Linear Guide Rail |

| C-axis Head Rotation | 0°–360° (ZHONGDA LEADER Robot Reducer) |

| A-axis Head Tilt | 0°–90° (ZHONGDA LEADER Robot Reducer) |

| Camera Brand | Hikvision |

| Blade Diameter | 350–500 mm |

| Control Center | Industrial computer + RTCP CNC controller + Cut Cam software + YUHAI Servo Motor |

| Main Motor | Self-developed 5-axis special motor, 22KW permanent magnet motor with frequency control |

| Electric Spindle Power | 7.5 KW |

| Router Max. RPM | 15,000 RPM |

| Total Power | 37.5 KW |

| Suction Cup Lifting Weight | 300 kgs |

| Machine Dimensions | L5750×W4150×H3500 mm |

| Water Consumption | 2 m³/h |

| Total Weight | 5 ton |

| Main Part Delivered Size | 5750×2200×2600 mm |

| Shipment | Main part delivered as whole (fits HQ container) |

Applications

The 5+1 Axis Bridge Saw is suitable for processing various materials in multiple industries:

Stone Fabrication Factories

Ideal for high-volume production of granite, marble, quartz, and sintered stone slabs, supporting thick material cutting (up to 120mm) and complex profiling for large-scale projects.

Commercial Construction Projects

Enables multi-angle beveling and 3D carving for building facades, interior walls, and public space stone installations, ensuring consistent quality and fast turnaround.

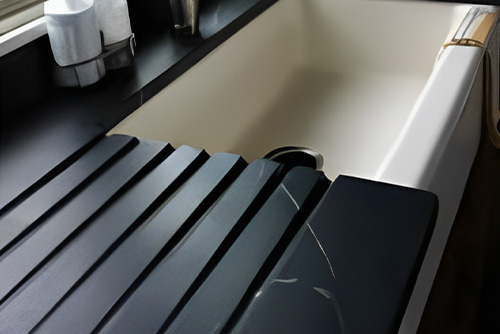

Residential Countertop Manufacturing

Provides automatic visual positioning and one-click processing for kitchen/bathroom countertops, sink cutouts, and edge milling, reducing manual labor and material waste.

Custom Stone Art & Decoration

The 0~360° rotating head and 0~90° tilting capability allow intricate 3D shaping, making it suitable for decorative stone pieces, fireplace surrounds, and bespoke interior elements.

Video Demonstrations

ZLBS-500CNC/5+1 Function Display

Performance Comparison

Compare our 5+1 Axis CNC Bridge Saw with traditional stone cutting solutions:

| Feature | Our 5+1 Axis CNC Bridge Saw | Traditional 3-Axis Bridge Saw | Standard Waterjet Cutter |

|---|---|---|---|

| Axes of Motion | 5+1 (A-axis 0~90° tilt + C-axis 0~360° rotation + X/Y/Z + rotary axis) | 3 (X/Y/Z only) | 3-4 (limited 4-axis) |

| Max. Cutting Thickness | 120mm (supports thick slab processing) | 80mm (limited to thin slabs) | 100mm (slow processing) |

| Cutting Precision | ±0.02mm (5+1-axis high-precision positioning) | ±0.5mm (manual adjustment required) | ±0.1mm (waterjet inherent limitation) |

| Material Waste | 5-8% (optimized path planning + auto positioning) | 15-25% (manual alignment + rough cutting) | 8-12% (abrasive consumption + kerf loss) |

| Complex Shapes | Excellent (full 3D carving + multi-angle beveling) | Limited (2D only, no beveling) | Good (2D complex, limited 3D) |

| Processing Speed | High (combined sawing + milling + auto positioning) | Medium (saw-only, slow for complex shapes) | Low (waterjet-only, abrasive-dependent) |

| Energy Efficiency | High (22KW permanent magnet motor, 40% energy saving) | Medium (constant motor load) | Low (high pump power + abrasive cost) |

Frequently Asked Questions

Absolutely. Send us your design drawings or specifications, and our team will produce a custom sample for you, along with a detailed production video to showcase the process. As a new, agile team, we pride ourselves on fast turnaround and flexible customization to meet your exact needs.

Our facility is located at 8 HAMPDEN RD, CRANBOURNE WEST VIC 3977. To arrange a visit, simply contact our team to book a time—we’ll provide a personalized tour of our production area, demonstrate our equipment in action, and answer any questions you have on-site.

Yes! Our machines are designed with user-friendly interfaces that are intuitive even for beginners. We provide a full operation manual, step-by-step video tutorials, and free ongoing online support to ensure you get up and running smoothly. We also offer optional on-site training sessions for your team.

We offer comprehensive after-sales service, including remote troubleshooting, on-site maintenance, and a stocked inventory of spare parts at our Cranbourne West facility. This ensures minimal downtime and fast resolution of any issues, with local support you can rely on.

As a new Australian-based company, we combine global manufacturing expertise with local service agility. We partner with top-tier suppliers to deliver high-quality machines at competitive prices, and our small, dedicated team provides personalized attention, fast response times, and flexible solutions tailored to your business. Plus, our local location means shorter lead times and easier communication—no international delays or language barriers.

Request More Information

Contact Us Directly

Our sales engineers are ready to help you find the perfect solution for your production needs.