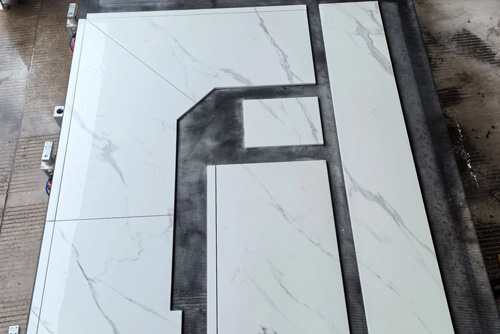

5 Axis CNC Stone Bridge Sawjet

It’s CNC Sawjet Machine,Type: ZLSJ-425CNC/5A, combined function of WaterJet and Bridge Saw. This machine can not only perform efficient Line cutting by Blade Saw, but also can process various curves and small angles by Water jet. It can process stones with high hardness , such as sintered stone, porcelain, ceramic, etc. Making it easy for stone chamfering, basin hole and internal angles processing. The processing method of this machine is flexible and convenient, with a high degree of automation and simple operation. It is currently the most advanced stone processing machine in the stone industry.

Quick Information

Key Features & Advantages

Automatic Thickness Measurement

Integrated laser thickness gauge automatically detects slab thickness during cutting, ensuring precise waterjet positioning and preventing material damage.

HD Visual Positioning System

20-megapixel Hikvision industrial camera with texture matching function, enabling precise visual positioning and automatic programming for complex patterns.

Automatic Slab Feeding System

Pneumatic automatic feeding system with 0.2MPa pressure, ensuring stable and efficient material loading to reduce manual labor.

Integrated High-Pressure Waterjet Pump

2-in-1 high-pressure pump with imported core components (USA/Italy/Taiwan/Germany) and built-in fan cooling system, saving factory space and ensuring stable performance.

Automatic Tool Change System

Self-developed five-axis specialized permanent magnet main motor with automatic tool change function, supporting quick tool switching for multi-process machining.

ZL CUT Software & Industrial Computer

21-inch industrial computer with ZL CUT software, featuring intuitive operation, texture matching, and compatibility with complex 3D machining programs.

Technical Specifications

| Model | ZLSJ-425CNC/5A |

|---|---|

| Machine Structure & Protection | Table tilt up to 85°; Hot-dip galvanized chassis; Sealed electrical cabinet with industrial AC; Auto greasing for X/Y/Z axes; 4 sliding doors with open-door power-off protection |

| Operation & Safety | Wireless operating handle; Built-in saw blade diameter probe |

| Max. Cutting Ranges | Saw blade: L3800×W2000×T90 mm (cutting) / L3400×W2000×T90 mm (chamfering); Waterjet: L3600×W2000×T60 mm |

| Axis Max Speed | X: 50 m/min, Y: 40 m/min (helical rack & pinion); Z: 8 m/min (ball screw) |

| Blade & Motor Specs | Blade diameter Ø400 mm; Saw blade motor: 22 kW (5-axis permanent magnet, 0-4000 r/min); Waterjet motor: 37 kW (0-50° tilt) |

| High-Pressure Pump | Imported core components (USA/Italy/Taiwan/Germany) with 2-in-1 fan cooling system |

| Control & Software | Hikvision 20MP camera (texture matching); YUHUI servo system; ZL CUT software + 21" industrial computer |

| Dimensions & Utilities | Machine size: 5850×3950×3960 mm; With sliding door: 6250×4930×3960 mm; Water consumption: 3 m³/h; Air pressure: 6 bar; Total weight: 13 ton; Total power: 69 kW |

| Delivery & Warranty | Delivery: 60 days; Warranty: 1 year; Free software license |

| Our Exclusive Advantages | 24/7 technical support; Lifetime free software updates; Customizable configurations; 1-year spare parts warranty; On-site installation & training |

Applications

The 5 Axis CNC Stone Bridge Sawjet is suitable for processing various materials in multiple industries:

Countertop Fabrication

Precision cutting and profiling for kitchen and bathroom countertops

Architectural Stone

Complex shapes and designs for building facades and interiors

Monuments & Memorials

Intricate engravings and shapes for commemorative structures

Furniture Components

Custom stone parts for high-end furniture and fixtures

Video Demonstrations

ZLSJ-425CNC/5A Gen Stone CNC SawJet WaterJet Cutting Machine For Porcelain Ceramic

Performance Comparison

Compare our 5-Axis CNC Bridge Sawjet with traditional stone cutting machines:

| Feature | Our 5-Axis CNC Bridge Sawjet | Traditional Bridge Saw | Standard Waterjet Cutter |

|---|---|---|---|

| Axes of Motion | 5 (full 5-axis linkage for complex angles) | 3 (X/Y/Z only) | 3-4 (limited 4-axis) |

| Cutting Precision | ±0.02mm (5-axis high-precision positioning) | ±0.5mm (manual adjustment required) | ±0.1mm (waterjet inherent limitation) |

| Material Waste | 5-8% (optimized path planning + precise positioning) | 15-25% (manual alignment + rough cutting) | 8-12% (abrasive consumption + kerf loss) |

| Processing Speed | High (combined sawjet cutting: fast sawing + precision waterjet finishing) | Medium (saw-only, slow for complex shapes) | Low (waterjet-only, abrasive-dependent) |

| Complex Shapes | Excellent (5-axis contouring + 3D profiling) | Limited (2D only, no beveling) | Good (2D complex, limited 3D) |

| 3D Machining | Yes (full 3D carving + beveling up to 85°) | No (only flat cutting) | Limited (simple 3D, low precision) |

| Material Compatibility | Granite, marble, porcelain, ceramic, quartz, engineered stone | Granite, marble (limited to thick slabs) | Most materials (but slow for thick stone) |

| Automation Level | High (auto tool change + thickness measurement + visual positioning) | Low (manual loading + alignment) | Medium (CNC control, but manual setup) |

| Operator Skill Required | Moderate (intuitive CNC interface + preset programs) | High (manual alignment + experience-dependent) | Moderate (CNC programming required) |

| Energy Efficiency | High (optimized motor + combined cutting reduces runtime) | Medium (constant saw motor load) | Low (high pump power + abrasive consumption) |

Frequently Asked Questions

Our machine is capable of cutting various natural and artificial stones including granite, marble, quartz, sandstone, limestone, engineered stone, and composite materials. The combined saw and waterjet technology allows for processing both hard and brittle materials with equal precision.

Standard delivery time is 45 days from the date of order confirmation. Custom configurations may require additional time. We provide regular updates on production status and can arrange expedited production for urgent orders with prior agreement.

We offer comprehensive training packages including on-site installation, operator training, and maintenance workshops. Our technical support team is available 24/7 via phone, email, and video conferencing. We also provide detailed operation manuals, video tutorials, and online knowledge base access.

Our standard warranty covers all mechanical and electrical components for 2 years from the date of installation. This includes parts replacement and technical support. Consumable items such as cutting tools, filters, and wear parts are covered for 3 months. Extended warranty options are available for up to 5 years.

Yes, we offer extensive customization options including table size, spindle power, additional axes, automated material handling systems, and specialized software packages. Our engineering team works closely with customers to develop tailored solutions for unique production requirements.

Request More Information

Contact Us Directly

Our sales engineers are ready to help you find the perfect solution for your production needs.